HISTORY / BACKGROUND

The Rapid Impact Compaction was originally developed in the early 1990’s by B.S.P. in conjunction with the British Military as a means of quickly repairing damaged aircraft runways. Dynamic energy is imparted by a 7.5 ton weight dropping from a controlled height onto a patented foot. Energy is transferred to the ground safely and efficiently as the RIC’s foot remains in contact with the ground. No flying debris is ejected. RIC densifies loose fill soils up to 20 feet deep or more. The benefit from the rapid compaction is it increases the bearing capacity of the soil, minimizes settlement and provides uniform support for a floor slab or foundation footing, while controlling vibrations to 2 inches per second within 30 feet of the drop point. RIC is a great alternative when compared to the time and cost of over-excavation and re-compaction.

RIC PROCESS

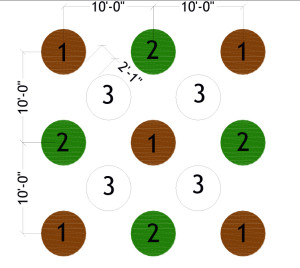

The compaction sequence is designed to work from the outside in; so that compaction energy can affect the soils at the deepest depths first …points designated 1… followed by compaction of soil in between in the upper zone …points 2 and 3. In this way the compaction energy is used efficiently to reach the deepest depths possible.

COMPACTION SEQUENCE

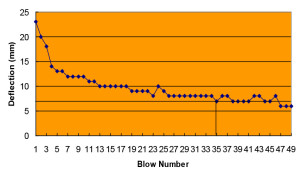

On-board monitoring tells operator when compaction is sufficient by monitoring deflection versus compaction hammer blow count. This Smart-Compaction system shuts off the machine when additional compaction effort results in only minimal compaction/deflection.

HOW RIC TECHNOLOGY WORKS

RIC increases the stiffness and shear strength of soils through the use of impact compaction effort. Specific benefits include:

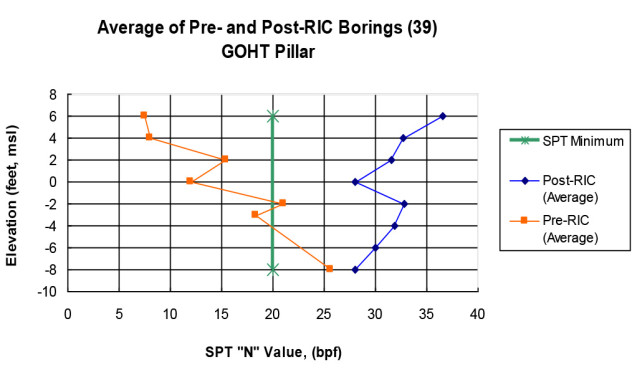

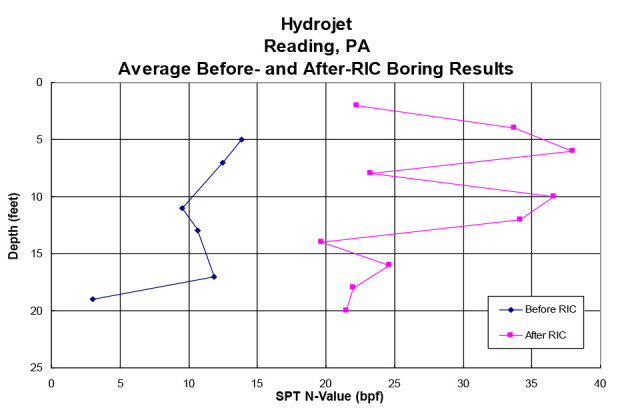

Increases Standard Penetration Resistance – the standard penetration resistance (N-Values) of loose granular soil can increase significantly. In developing an RIC specification for a project the minimum target blow count for the performance required should be specified.

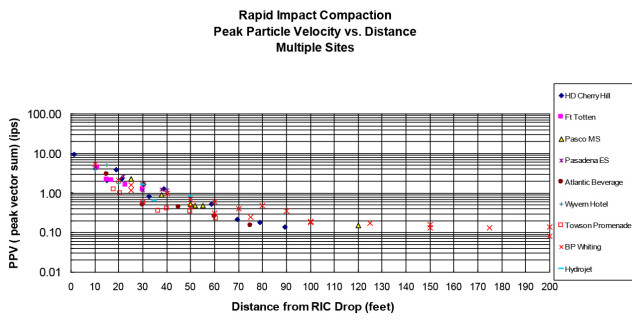

Use within 30 feet of a Building – Because Rapid Impact Compaction provides a low magnitude of impact loading at a very high frequency, the peak particle velocity remains relatively low (less than 2 inches per sec) at a distance of 30 feet from the source. This is different from Deep Dynamic Compaction which has a low frequency and a high magnitude of loading so vibrations are greater from DDC when compared to RIC.

Quality Assurance

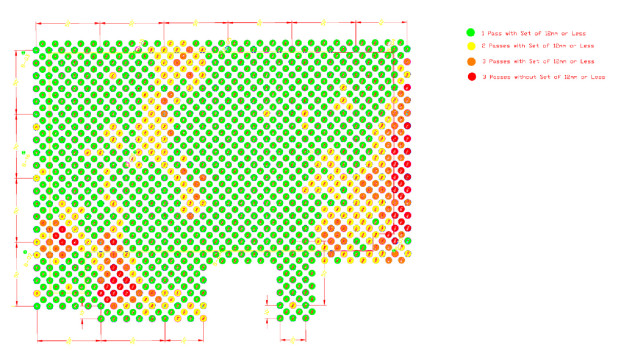

The energy and deflection of the soil is monitored and recorded at each location, which allows the geotechnical engineer to determine when effective treatment is complete. It also enables the engineer to identify weak zones (red dots) or debris zones throughout the pad so that any remedial actions that may be required can be minimized resulting in cost savings.

Buried stumps were found as a result of RIC. RIC provided an investigation tool in this instance. The previously-undetected debris was removed and replaced with sand.

RIC APPLICATIONS

Small Buildings and Floor Slabs – RIC has been used to improve soil under 2 to 3-story building footings and floor slabs.

Replace Surcharging – Instead of using a surcharge to consolidate the soil under a static weight, Rapid Impact Compaction consolidates it immediately.

Replace Over Excavation – Loose fills or soils can be consolidated immediately without the need to replace the soil.

Improve Lateral Load Capacity for Piles – The lateral load capacity of a pile is greatly influenced by the stiffness of the upper 10 feet of soil in which it is driven. By densifying the upper layers of soil the lateral capacity is greatly increased.

Rapid Impact Compaction – Frequently Asked Questions