Microtunneling is a trenchless construction method used to install pipelines beneath highways, railroads, runways, harbors, rivers, and environmentally sensitive areas.

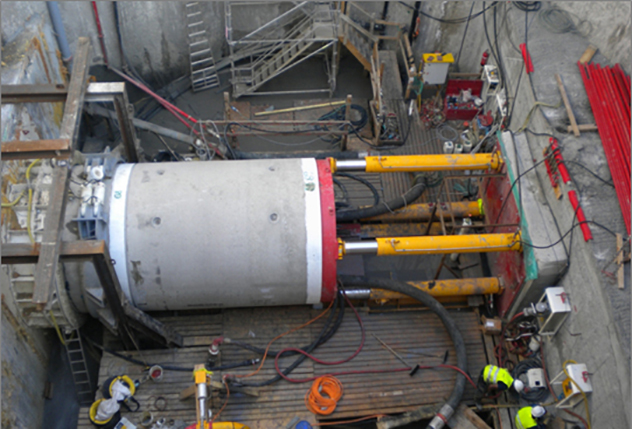

Microtunnels are installed using a remote-controlled drilling and pipe-jacking system. The drilling system provides continuous support to the excavation face by applying mechanical or fluid pressure to balance groundwater and earth pressures.

Support at the excavation face is a key feature of microtunneling, distinguishing it from traditional open-shield pipe-jacking and therefore is a preferred method when tunneling below the groundwater table and in caving soils.

MICROTUNNELS VS OPEN CUT OR TRENCHING

■ Drill face support lowers risk of caving and settlement of roadways, buildings and adjacent utilities

■ Can be performed in soil and rock

■ Less excavation, so fewer spoils to remove

■ Tunneling activity is independent of weather conditions

■ Higher production rates

TYPICAL APPLICATIONS

■ Combined Sewer Overflow Systems

■ Sea, lake or river outfall of sewer, water and industrial fluids

■ Road crossings, streets, railways, buildings, airports, parks

■ Desalinization plant water intake tunnels

■ Gas, electricity, cable, and telecommunication networks conduits

Microtunneling at SDTT Altamira Landfall Executed

WHY GEOSTRUCTURES

■ Provide Design-Build Services for Shafts, Microtunnels and Ground Improvement

■ Specialize in large diameter pipe jacking with long drives, resulting in fewer shafts

■ Expert know-how with experience in more than 25 countries

■ Hold World record tunnel lengths for outfall projects

■ Currently fleet of 12 TBMs